Golez: This will soon by a game changer in the field of construction and manufacturing, especially in transportation equipment like planes, cars, trains, ships, making travel much safer for mankind:

"Using computer modeling, the (MIT) researchers have designed a new -- currently nameless -- material, a sponge-like configuration that is just 5% the density of steel and about 10 times as strong.

"This makes it both extraordinarily light but able to carry heavy loads -- properties that the researchers think make the material ideal for future use in design or architecture.

"We can use this kind of material as a substitute for a lot of materials used in infrastructure, like bridges, or as a substitute for steel and concrete," says Zhao Qin, one of the research scientists who worked on the development of the material at MIT's Department of Civil and Environmental Engineering."

"We can use this kind of material as a substitute for a lot of materials used in infrastructure, like bridges, or as a substitute for steel and concrete," says Zhao Qin, one of the research scientists who worked on the development of the material at MIT's Department of Civil and Environmental Engineering."

Are we one step closer to being able to use the world's strongest material?

By Nicola Davison, CNN

Updated 1333 GMT (2133 HKT) January 13, 2017

Photos: Incredible innovations: These materials could change the world

Transparent wood – Once stripped of lignin, the wood is injected with an epoxy to strengthen it. Research suggests that transparent wood may one day be used as a substitute to glass.

Hide Caption

6 of 10

Photos: Incredible innovations: These materials could change the world

At London Design Festival last year, architect Alison Brooks revealed "The Smile": a 34-meter long structure which is the most complex structure ever to be made out of cross-laminated timber.

Hide Caption

7 of 10

Photos: Incredible innovations: These materials could change the world

The large structure shows the potential of cross-laminated American tulipwood, which is stronger than concrete.

Hide Caption

8 of 10

Photos: Incredible innovations: These materials could change the world

Glowing concrete – In July last year, Mexican scientist José Carlos Rubio Avalos created glow-in-the-dark cement.

Hide Caption

9 of 10

Photos: Incredible innovations: These materials could change the world

The flowing material soaks in the suns rays during the day, and emits light at night.

Hide Caption

10 of 10

Photos: Incredible innovations: These materials could change the world

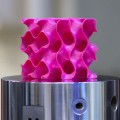

Graphene-gyroid – Researchers at the Massachusetts Institute of Technology have designed a new material that is 10 times stronger than steel.

Hide Caption

1 of 10

Photos: Incredible innovations: These materials could change the world

Graphene-gyroid – The MIT researchers discovered that fusing small flakes of graphene -- widely regarded as the world's strongest known material -- into a gyroid-shaped structure creates a new material that is unusually light but still distinctly strong.

Hide Caption

2 of 10

Photos: Incredible innovations: These materials could change the world

Graphene-gyroid – One of the researchers on the project, Zhao Qin, says he thinks that the graphene-gyroid material could one day be widely used in engineering and architecture.

Scroll through the gallery to see other examples of extraordinary materials.

Scroll through the gallery to see other examples of extraordinary materials.

Hide Caption

3 of 10

Photos: Incredible innovations: These materials could change the world

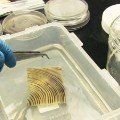

Transparent wood – In August last year, scientists at the University of Maryland created transparent wood.

Hide Caption

4 of 10

Photos: Incredible innovations: These materials could change the world

Transparent wood – First the scientists remove lignin, an organic substance that is responsible for giving wood a "yellow-ish" color.

Hide Caption

5 of 10

Photos: Incredible innovations: These materials could change the world

Transparent wood – Once stripped of lignin, the wood is injected with an epoxy to strengthen it. Research suggests that transparent wood may one day be used as a substitute to glass.

Hide Caption

6 of 10

Photos: Incredible innovations: These materials could change the world

At London Design Festival last year, architect Alison Brooks revealed "The Smile": a 34-meter long structure which is the most complex structure ever to be made out of cross-laminated timber.

Hide Caption

7 of 10

Photos: Incredible innovations: These materials could change the world

The large structure shows the potential of cross-laminated American tulipwood, which is stronger than concrete.

Hide Caption

8 of 10

Photos: Incredible innovations: These materials could change the world

Glowing concrete – In July last year, Mexican scientist José Carlos Rubio Avalos created glow-in-the-dark cement.

Hide Caption

9 of 10

Photos: Incredible innovations: These materials could change the world

The flowing material soaks in the suns rays during the day, and emits light at night.

Hide Caption

10 of 10

Photos: Incredible innovations: These materials could change the world

Graphene-gyroid – Researchers at the Massachusetts Institute of Technology have designed a new material that is 10 times stronger than steel.

Hide Caption

1 of 10

Photos: Incredible innovations: These materials could change the world

Graphene-gyroid – The MIT researchers discovered that fusing small flakes of graphene -- widely regarded as the world's strongest known material -- into a gyroid-shaped structure creates a new material that is unusually light but still distinctly strong.

Hide Caption

2 of 10

Photos: Incredible innovations: These materials could change the world

Graphene-gyroid – One of the researchers on the project, Zhao Qin, says he thinks that the graphene-gyroid material could one day be widely used in engineering and architecture.

Scroll through the gallery to see other examples of extraordinary materials.

Scroll through the gallery to see other examples of extraordinary materials.

Hide Caption

3 of 10

Photos: Incredible innovations: These materials could change the world

Transparent wood – In August last year, scientists at the University of Maryland created transparent wood.

Hide Caption

4 of 10

Photos: Incredible innovations: These materials could change the world

Transparent wood – First the scientists remove lignin, an organic substance that is responsible for giving wood a "yellow-ish" color.

Hide Caption

5 of 10

Photos: Incredible innovations: These materials could change the world

Transparent wood – Once stripped of lignin, the wood is injected with an epoxy to strengthen it. Research suggests that transparent wood may one day be used as a substitute to glass.

Hide Caption

6 of 10

(CNN)It has been 15 years since the discovery of graphene, an ultra-thin sheet of carbon that is thought to be the strongest material on the planet.

Although graphene is much stronger than steel, turning it into a useful material for architecture has so far proved tricky. Translating two-dimensional graphene into a three-dimensional structure -- the building blocks of a material -- has been difficult. Graphene "wants" to stay two-dimensional.

That may be set to change thanks to a team of researchers at MIT.

Using computer modeling, the researchers have designed a new -- currently nameless -- material, a sponge-like configuration that is just 5% the density of steel and about 10 times as strong.

This makes it both extraordinarily light but able to carry heavy loads -- properties that the researchers think make the material ideal for future use in design or architecture.

"We can use this kind of material as a substitute for a lot of materials used in infrastructure, like bridges, or as a substitute for steel and concrete," says Zhao Qin, one of the research scientists who worked on the development of the material at MIT's Department of Civil and Environmental Engineering.

The origins of graphene

Graphene was first discovered in 2002 by Andrew Geim, a physics professor at the University of Manchester.

Geim was interested in seeing how microscopically thin layers of carbon might behave by themselves.

He looked to graphite, the substance used in pencils that is made of thin, weakly bonded layers of carbon (the reason why dragging a pencil across a piece of paper will produce a visible line).

Geim used Scotch tape to peel away ever-thinner "flakes" of graphite until he eventually had a layer that was just one atom thick: graphene, the first two-dimensional material discovered. Under an atomic microscope, graphene looks like a flat lattice of hexagons in a honeycomb arrangement.

As well as being incredibly strong, graphene is pliable like rubber and can carry a thousand times more electricity than copper.

Due to these unusual properties, the media has been quick to hail graphene a "wonder material."

But while many patents have been filed for all sorts of applications -- from bendable computer screens and solar cells to long-life batteries -- so far turning the ideas into materials or practical products has proven difficult.

Putting strong materials to use

The researchers at MIT used computer models to see if it might be possible to make two-dimensional flakes of graphene into three-dimensional structures.

To do this they needed the flakes to fuse, something they achieved through applying heat and pressure in cycles hundreds of times until the flakes formed a stable, integrated form.

The researchers then looked to biological materials, including butterfly wings, coral and sea urchins, for naturally occurring geometric shapes that could be a template for the new graphene material.

One shape they observed at the microscopic level was the "gyroid," a structure with a continuous surface that is also porous, a bit like a sponge.

Gyroid shapes have an enormous surface area in proportion to their volume. Fused graphene flakes that are arrayed in this geometry, the researchers found, formed an unusually light yet strong material.

"Once they combine and fuse together, all the flakes contribute to the strength of the overall structure," Qin explains. Similarly, a piece of paper is flimsy until it is rolled into a tube and stood on end.

Since graphene, for now, is prohibitively expensive and difficult to manufacture, other materials such as polymers or metals could instead take advantage of the inherent strength of the gyroid geometry. Qin plans to experiment with cellulose and silk -- organic materials with high carbon content.

Though there is research still to do, Qin thinks one day the graphene-gyroid material could be widely used in engineering and architecture, especially in more sustainable projects. Using a material that is much lighter than steel would substantially lower a building's carbon footprint.

"We can effectively reduce the carbon oxide emission," Qin says. "That will help make the construction more green and healthier in the future."

No comments:

Post a Comment